Laborpumpen (Peristaltikpumpen)

siehe auch: Adapter für Peristaltikpumpen / Schläuche für Peristaltikpumpen| Laboratory Pumps Introduction | ||

| Fluid handling is a common need in most labs. With smaller dispense requirements and longer-to-continuous duty operations, smaller more accurate and robust pumping solutions are necessary. To meet these needs, we now offer pumping solutions from sister IDEX® Corporation business units: revolutionary ISMATEC® peristaltic pumps and innovative Sapphire EngineeringTM syringe pump alternatives (PVMs and IPVs). | ||

| Features

/Benefits of Peristaltic Pumps

- Pumping by Speed or Flow Rate / Dispensing by Volume or Time / Interval Dispensing with a Pause / Dispensing a Volume within a Pre-set Time / Interval Dispensing with a Pre-set Number of Dispensing Cycles / Roller Back-steps for Drip-free Dispensing / Contamination Free Pumping / - Pumping Sterile Media / High Accuracy / High Repeatability / Multi-Channel Pumping |

Features

/Benefits of PVMs /IPVs

PVM (Pump Valve Module) Aspirating/Dispensing System - For automated pipetting, diluting and dispensing / Self-contained, stepper motor driven module / Uses IPVs - 100% software compatible with Cavro™ XP-3000 syringe pumps / Many programmable functions - RS-232, RS-485 and CAN BUS communication and control / Selectively work with up to 15 PVMs |

|

|

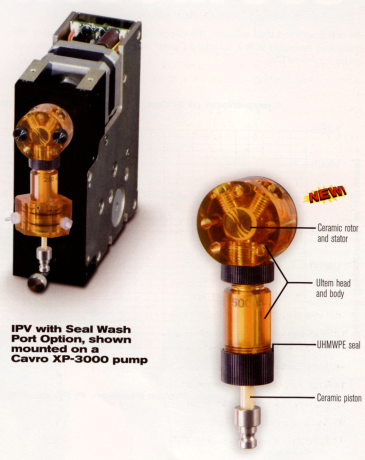

IPV

(Integrated Piston/Valve)

- For use on PVMs and direct plug-and-play use on Cavro XP-3000 syringe pumps - Accuracy and precision identical to traditional syringes and valves - Lasts up to 20 times longer than traditional products, with significant lifetime cost savings - Made of durable, chemically resistant materials - Set-up in less than five minutes / Requires no routine maintenance / 50µL - 5.0mL volumes available,with or without a seal wash option |

|

| Peristaltic Pumps Introduction | ||

| For a Wide Range of Applications | ||

| With

a wide range of tubing available, ISMATEC peristaltic tubing pumps are

capable of pumping almost any media, including corrosive or sterile. - Many tubing materials available / Independent, yet simultaneous delivery of various media at different flow rates (multichannel pumps-up to 24 channels) / Self-priming from a depth of up to 8 m / Reversible rotation direction / Extremely accurate dispensing with calibrateable, microprocessor controlled drives |

The peristaltic pump principle of ISMATEC

pumps.

The peristaltic pump principle of ISMATEC

pumps. |

|

| Inexpensive

to Maintain - Practically no maintenance costs - Nearly maintenance-free - Tubing is the only part to wear No expensive seals, valves or diaphragms - Ready again after simple tubing change - High quality and precision deliver optimum performance even after many years of intensive use |

||

Continuous Duty

Continuous Duty |

Safe and

Easy to Use - Developed for continuous duty, 24 hrs./day, 7 days/week - No contamination of the fluid or the pump / Immune to dry-running - No valves to clog, hang up or need servicing / No seals which can leak - No syphoning effect when the pump stops / No flushing and cleaning required Immediately adaptable to new application - New tubing = pump is ready for use - Fast filling and emptying thanks to a MAX key and reversible flow direction |

Rotation Direction Reversible

Rotation Direction Reversible |

| Ismatec Peristaltic Pump Paremeters | |||

| Features | Pumping | ||

| Max. Flow Rate | 68 ml /min | Multi-channel system | yes |

| Min. Flow Rate | <0.001 mL /min | Low Shearing Forces | low |

| Max. Diff. Pressure | ~1-2.5 bar (~15-36 psi) | Contamination Free | yes |

| Suction Lift, Water | 7-8m | Reverse Operation | yes |

| Dead Volume | practically none | Pulsation Ratio | low to moderate |

| Chemical Compatibility | depens on tubing | Media | |

| Accuracy, Repeatability | high | Pump particles | yes |

| Self-Priming | yes | Viscous Liquids | yes |

| Dry-Running | yes | Pump Living Cells | yes |

| Maintenance | tubing replacement | Foaming / Gas / Corrosive / Aggressive | yes |

| Low Flow Peristaltic Pumps | |||||

|

- 4 to 24 Channels - 0.0004 to 44 mL/min Flow Rates - For dispensing and continuous flow applications / Very High Repeatability on All Channels - Lowest Pulsation, Highest Accuracy |

|||||

| ISMATEC®

high accuracy, multichannel peristaltic tubing pumps are ideal for both

continuous pumping and discrete dispensing applications. Smooth, low

pulse and repeatable operation is ensured by a unique planetary drive

system. These pumps are easily calibrated and can be programmed to dispense by flow rate, volume or time, making them adaptable to many applications. A pause time of up to 999 hours can also be programmed between dispense volumes. There's even a back-step routine option to prevent drips as well as a stand-by mode. The LED display indicates the current setting. Priming and flushing are accomplished with a simple push of a button on the membrane key pad, without affecting programmed settings.Choose from ISMATEC's line of standard or low speed units, each available with 4, 8, 12 and 24 channels. |

|

||||

| Speed | Model | Flow rate (mL /min per channel) | |||

| Standard | IPC | 0.002-44 | |||

| Low | IPC-N | 0.0004-11 | |||

| Speed

(rpm) coupled with the selection of tubing ID determines actual flow

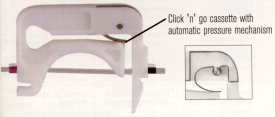

rate per channel. The standard Click `n' go cassettes, supplied with

each pump, feature an automatic pressure setting. Maximum differential

pressure is 15 psi (1.0 bar), depending on tubing material. Tubing with

small IDs and/or optional cassettes with pressure lever may enable

higher pressures.Operations can be controlled via RS-232 computer

interface. Analog input and output controls via contact closure include:

speed control (0-5 or 0-10 V; 0-20 or 4-20mA), speed output (0-10 V or

0-11 kHz), start/stop, rotation direction and autostart. Download

drivers for LabVIEW Software at no cost from www.ismatec.com,

"Downloads".

Each unit is housed in lacquered stainless steel. Typical applications for these Ismatec Peristaltic Tubing Pumps include: -Toxicological in-vitro use - Perfusion of animal tissue slices - Sampling from tablet dissolution systems / Flow injection analyzers |

|||||

| Specifications | |||

| Motor typ | DC motor | ||

| Speed IPC /IPC-N | 0.4-45rpm / 0.11-11.25rpm | ||

| Speed setting | 1-100% resolution 0.1% | ||

| Flow rate setting | µL/min or mL/min | ||

| Power consumption | 30W | ||

| Power supply | 230 V /50Hz,115V /60Hz adjustable | ||

| Protection rating | IP 30 | ||

| Dimension / Weight | |||

| Depth/Width/Heigh (mm) | Weight | ||

| 4 channels | 180 x 175 x 130 | 4.6 | |

| 8 channels | 220 x 175 x 130 | 5.1 | |

| 12 channnels | 260 x 175 x 130 | 5.8 | |

| 24 channnels | 380 x 175 x 130 | 7.9 | |

| Low Flow Peristaltic Tubing Pumps | |||||

| Order No. | Model | Flow Rates (mL/min per channel) | Channels | Speed (rpm) | |

| Standart Speed (IPC) | |||||

| ISM930 | IPC 4 | 0.002-44 | 4 | 0.4-45 | |

| ISM931 | IPC 8 | 0.002-44 | 8 | 0.4-45 | |

| ISM932 | IPC 12 | 0.002-44 | 12 | 0.4-45 | |

| ISM934 | IPC 24 | 0.002-44 | 24 | 0.4-45 | |

| Low Speed (IPC-N) | |||||

| ISM935 | IPC 4 | 0.0004-11 | 4 | 0.11-11.25 | |

| ISM936 | IPC 8 | 0.0004-11 | 8 | 0.11-11.25 | |

| ISM937 | IPC 12 | 0.0004-11 | 12 | 0.11-11.25 | |

| ISM939 | IPC 24 | 0.0004-11 | 24 | 0.11-11.25 | |

| Compact Reglo Peristaltic Pumps |

||

|

- 2 and 4 Channels / 0.002

- 57mL/min Flow Rates / ISMATEC®'s

Smallest Calibrateable Dispensing Pump /

Foot Print Only 178 x 100 mm and

only 13.5cm high! / High

Repeatability ISMATEC® compact REGLO peristaltic tubing pumps offer two or four channels in a small footprint. The eight rollers of these variable-speed pumps provide smooth, consistent flow. Two control options are available - programmable digital and analog. |

||

| REGLO

Programmable Digital Pumps with dispensing function

The digital pump version is easily calibrated and programmed via a 6-button membrane keypad and LED display interface. Dispense by flow rate, volume or time. A pause time of up to 999 hours can also be programmed between dispense volumes. Back-steps can also be programmed to prevent drips.Control operations remotely via RS-232 computer interface. An analog speed output signal is available (see REGLO Analog, below). Activate start/stop and autostart with analog contact closure input signals. Drivers for LabVIEW Software are available at no cost from www.ismatec.com, "Downloads." |

|

REGLO

Analog Pumps without dispensing function

Flow for the analog version is controlled by setting the pump speed (rpm). Speed is adjustable from 2-99% in 1 % steps via a 2-digit potentiometer. Analog input and output controls via contact closure include: speed control (0-5 or 0-10 V; 0-20 or 4-20mA), speed output (2-channel: 0-8 kHz; 4-channel: 0-5 kHz), start/stop and rotation direction. The combination of pump speed (rpm) and the ID of the selected tubing determines actual flow rate per channel. Standard Click `n' go cassettes, supplied with each pump, feature an automatic pressure setting. Maximum differential pressure is 15 psi (1.0 bar), depending on tubing material. Tubing with small IDs and/or optional cassettes with pressure lever may enable higher pressures. |

| Specifications | |||

| Reglo Digital | Rego Analog | ||

| Motor type | DC motor | DC motor | |

| Speed | 2-channnel 4-channel | 1.6-160 rpm 1.0-100 rpm | 3.2-160 rpm 2.0-100 rpm |

| Speed setting | rpm, resolution 0.1 rpm | 2-99% resolution 1% 2-digit potentiometer | |

| Flow rate setting | µL/min or mL/min | NA | |

| Power consumption | 20 W | 20 W | |

| Power supply | 85-264V / 47-60Hz | 230V /50Hz, 115V /60Hz adjustable | |

| Protection rating | IP 30 | IP 30 | |

| Depth/Width/Height | 2-channel 4channel | 178 x 100 x 135mm 190 x 100 x 135mm | 178 x 100 x 143mm 190 x 100 x 143mm |

| Weight | 2-channel 4-channel | 2.0kg 2.1kg | 2.0kg 2.1kg |

| Compact Reglo Peristaltic Tubing Pumps | ||||||

| Artikelnummer | Model | Flow rates (mL/min per channel) | Channels | Rollers | Speed (rpm) | |

| Digital | ||||||

| ISM832 | MS-2/08 | 0.002-57 | 2 | 8 | 1.6-160 | |

| ISM834 | MS-4/08 | 0.002-35 | 4 | 8 | 1.0-100 | |

| Analog | ||||||

| ISM829 | MS-2/08 | 0.004-57 | 2 | 8 | 3.2-160 | |

| ISM827 | MS-4/08 | 0.003-35 | 4 | 8 | 2.0-100 | |

| FIXED-SPEED

RACK-MOUNT PERISTALTIC PUMPS - Compact Size - 2 and 4 Channels - 0.021 to 21.0 mL/min Flow Rates |

|

||||||

| ISMATEC®

Fixed Speed, Rack-Mount Peristaltic Pumps are ideal for limited space

applications. These compact, 2 or 4 channel economical pumps are simple

to operate - a quick flick of the on/off switch and the eight rollers

and synchronous motor ensure steady, reproducible flow rates. Tubing

changes are equally simple, and can even be accomplished while the pump

is running. The flow rate of these fixed speed pumps is determined by the

inner diameter of the selected tubing. Each pump is supplied with a set

of standard Click `n' go tubing cassettes, with automatic pressure

setting. Maximum differential pressure is 15 psi (1.0 bar), depending on

tubing material. Tubing with small IDs and/or optional cassettes with

pressure lever may enable higher pressures. Pumps are also

supplied with a 6-foot cord and mounting rod (5 1/2" L x 1/2"

diameter). Typical applications for these pumps are multichannel delivery processes requiring a constant flow rate, such as: - Pump seal wash - Sipper pump for flow-through cuvettes - Long-term determination of environmental influences / Feeding of overlow level control systems |

ISMATEC FIXED-SPEED, RACK-MOUNT PUMPS | ||||||

| Artikelnummer | Model | Flow rates (mL/min per channel) | Channels | Rollers | Speed (rpm) | ||

| 230 Volts (European) | |||||||

| ISM847 | MS-CA 2/820 | 0.021-7.1 | 2 | 8 | 20 | ||

| ISM849 | MS-CA 2/860 | 0.064-21.0 | 2 | 8 | 60 | ||

| ISM852 | MS-CA 4/820 | 0.021-7.1 | 4 | 8 | 20 | ||

| ISM853 | MS-CA 4/840 | 0.043-14.0 | 4 | 8 | 40 | ||

| Specifications | |||

| Motor type | Synchronous motor | ||

| Speed | 20, 40 or 60 rpm | ||

| Power consumption | 8 W | ||

| Power supply | 230 V (50/60Hz) | ||

| Protection rating | IP 30 | ||

| Depth/Width/Height 2-channel 4-channel | 125 x 88 x 135mm 145 x 88 x 135mm | ||

| Weight 2-channel 4-channel | 1.2kg 1.3kg | ||

| Tubing Cassettes | |

| Developed and Consistently Improved by ISMATEC® | |

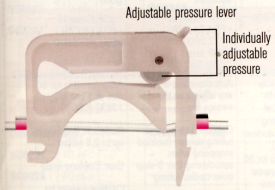

| Click'n' go

Cassattes (Standart) Advantages: - Automatic tubing pressure; no readjustment necessary / Ideal for non-monitored, long-time use Please Note: Click 'n' go cassettes are not suitable for differential pressure greater than 1 bar (15 psi). For these conditions you should choose the pressure lever cassettes. |

|

|

Pressure

Lever Cassettes (Optional) The optional pressure lever allows you to set a different tubing pressure for each channel. Depending on the application, tubing material and diameter, an optimally adjusted tubing pressure can be set. To maintain constant flow rates it may be necessary to periodically adjust the tubing pressure. |

| Foot Switch | |

| The ISMATEC foot switch for start/stop is very practical for use with pumps as dispensing systems, e.g. for filling tubes, bottles etc. A foot switch provides the start/stop signal required, allowing hands-free activation of the filling system. The switch's protection rating is IP21 (higher safety categories, e.g. IP67 on request). A 6-foot (1.8m) cable is included. |  |

| Artikelnummer | Model | Material | Adapters Req'd? | |||

| Click `n' go Spare Cassettes (1) | ||||||

| IS3510 | MS/CA Click '5' go | POM-C | No | |||

| IS3710 | CA Click 'n' go | POM-C | Yes (2) | |||

| Pressure Lever Optional Cassettes | ||||||

| IS0649 | MS/CA Pressure Lever | POM-C | No | |||

| IS3629 | MS/CA Pressure Lever | PVDF (3) | No | |||

| IS0122 | CA Pressure Lever | POM-C | Yes (2) | |||

| IS3820 | CA Pressure Lever | PVDF (3) | Yes (2) | |||

| Replacement Adapters for CA Cassettes (2) | ||||||

| IS0123 | Adapter for CA Cassettes | POM-C | ---------- | |||

| IS3861 | Adapter for CA Cassettes | PVDF (3) | ---------- | |||

| Artikelnummer | Beschreibung | |||||

| ISM016 | IPC and IPC-N (firmware version older than 4.00) | |||||

| IS10039 | IPC and IPC-N (from firmware version 4.00) | |||||

| ISM891 | REGLOAnalog | |||||

| ISM894 | REGLO Digital | |||||

| (1) Included with all Ismatec cassette-style pumps. (2) When ordering replacement CA Cassettes two Adapters per cassette must also be ordered (3) PVDF offers higher chemical resistance, | ||||||

| Confluent ™ PVM | |

| Complete Asp irnting / Dispensing System / Uses Long Life IPVs | |

| The compact digital Confluent PVM (Pump and Valve Module) is a selfcontained, stepper motor driven module. This product is designed for various liquid handling applications such as automated pipetting, diluting and dispensing. The Confluent PVM uses the patent pending IPV (Integrated Piston/Valve), which meets and exceeds the precision accuracy of traditional syringe/plug valve systems while offering up to 20x the life. This translates into a major cost savings. Confluent PVM is 100% software compatible with the Cavro™ XP-3000 syringe pump (standard resolution). It can be operated as a stand-alone module or in automated instruments controlled by an external computer or microprocessor. Each pump has RS-232, RS-485 and CAN BUS connections for communication with a controlling device using Data Terminal protocol. |  |

| SOFTWARE

FEATURES - 100% plug and play software compatible with Cavro XP-3000 syringe pumps /Resolution of 3,000 full steps per stroke / Programmable ramps, cut-offs, backlash compensation, plunger speeds, delays and loops / Select piston speed / Absolute and relative positioning of pistons / Start and terminate piston movement / Check pump with self-test / Selectively work with up to 15 PVMs |

|

| The

performance of each PVM is tested and documented before shipment. The

Confluent PVM meets the CE EMC Class B specifications. Please see the

following table for more specifications. The PVM can be used with your choice of IPV, from 50µL - 5.0mL volumes, with or without optional seal wash ports. |

|

| Confluent PVM Specifications | |

| Piston Drive | DC stepper motor with a step control sensor, self lubricating, 30mm stroke length |

| Motor Resolution | 3,000 steps, standard resolution |

| Dispense Speed (full stroke) | 1.1 sec - 600 sec |

| Valve Drive | DC stepper motor with optical encoder |

| Valve Drive Speed | 250ms between adjacent ports |

| Valve Tubing Connections | 1/4-28 flat bottom fittings |

| Power Requirements | 24 VDC ± 5%; 1.2A |

| Baud Rate | 9,600 to 38,400 (RS-232, RS-485) |

| Input/Output | 2 input TTL; 3 output TTL |

| Dimensions | 5.00" H x

1.80" W x 4.50" D (127mm H x 45mm W x 114mm D) |

| Weight | 2.5Ibs, (1.1 kg) |

| Operating Range Temperature Humidity |

17° to 37° C 10 - 85% R.H. noncondensing |

| Storage Range Temperature Humidity |

5° to 45° C 10 - 95% R.H. noncondensing |

| Confluent PVM /IPV Kits (1) | ||

| With IPV | ||

| Artikelnummer | ||

| 81-1003K-4908-50-07 | PVM with 50µL IPV | |

| 81-1003K-4908-100-07 | PVM with 100µL IPV | |

| 81-1003K-4908-250-07 | PVM with 250µL IPV | |

| 81-1003K-4908-500-07 | PVM with 500µLIPV | |

| 81-1003K-4908-1000-07 | PVM with 1.0mL IPV | |

| 81-1003K-4908-2500-07 | PVM with 2.5mL IPV | |

| 81-1003K-4908-5000-07 | PVM with 5.0mL IPV | |

| With IPV and Seal WashPort | ||

| 81-1003K-4908W-50-07 | PVM with 50µL IPV | |

| 81-1003K-4908W-100-07 | PVM with 100µL IPV | |

| 81-1003K-4908W-250-07 | PVM with 250µL IPV | |

| 81-1003K-4908W-500-07 | PVM with 500µL IPV | |

| 81-1003K-4908W-1000-07 | PVM with 1.0mL IPV | |

| 81-1003K-4908W-2500-07 | PVM with 2.5mL IPV | |

| 81-1003K-4908W-5000-07 | PVM with 5.0mL IPV | |

| Confluent ™ IPV Patent pending |

|

| - Accuracy and Precision Identical to Traditional Syringes and Valves / Significant Lifetime Cost Savings / Direct Plug-and-Play Products / Made of Durable, Chemically Resistant Materials | |

| The Sapphire

Engineering™ Confluent Integrated Piston/Valves (IPVs) offer precision

and accuracy equivalent to traditional glass barrel/Teflon® syringes

with Kel-F®/Teflon plug valves. However, extensive tests show the

Confluent IPV will outlast traditional syringe/valves by as much as 20

fold, yielding major lifetime cost savings. By selecting the seal wash

option, you can extend Confluent IPV life even longer when using it with

aggressive or difficult fluids (such as salt buffer solutions). The

Confluent IPV requires no routine preventive maintenance such as

cleaning and nut tightening, essential with conventional syringes. How

does the Confluent IPV deliver such dramatic savings? The IPV uses

cutting-edge piston technology to pump fluid via positive displacement

in lieu of a traditional syringe. Secondly, a ceramic-on-ceramic shear

valve replaces the more-common polymer plug valve. These innovations,

combined with proprietary surface finishing processes on the ultra-hard

piston, rotor and stator surfaces, mean significantly less wear, less

downtime and reduced cost of ownership. Select a Confluent IPV for use on a Confluent PVM, or as a direct plug-and-play replacement for an existing syringe/ valve on a Cavro XP-3000 syringe pump. Getting up and running takes as little as five minutes. Choose from the available 50µL - 5.0mL volumes, with or without a seal wash option. Use Confluent IPVs in traditional syringe valve applications, i.e. to aspirate/ dispense small, precise volumes, such as: - Automated pipetting / Lab-on-a-chip infusion / FIA (Flow Injection Analysis) dosing / Titrations / System rinse/wash The wetted materials of the IPV are Ultem®, Tefzel®, TZP (Zirconia) ceramic, Alumina ceramic, UHMWPE and Viton®. Please contact us regarding custom solutions for instrument manufacturers, including alternative materials and configurations. |

|

| Replacement Confluent IPVS for Confluent PVM | ||

| With 3-Way Ceramic "V" Valve | ||

| Artikelnummer | ||

| 98-4908-50-07 | 50µL IPV | |

| 98-4908-100-07 | 100µL IPV | |

| 98-4908-250-07 | 250µL IPV | |

| 98-4908-500-07 | 500µL IPV | |

| 98-4908-1000-07 | 1.0mL IPV | |

| 98-4908-2500-07 | 2.5mL IPV | |

| 98-4908-5000-07 | 5,0mL IPV | |

| With 3-Way Ceramic "Y" Valve and Seal Wash Port | ||

| 98-4908W-50-07 | 50µL IPV | |

| 98-4908W-100-07 | 100µL IPV | |

| 98-4908W-250-07 | 250µL IPV | |

| 98-4908W-500-07 | 500µL IPV | |

| 98-4908W-1000-07 | 1.0mL IPV | |

| 98-4908W-2500-07 | 2.5mL IPV | |

| 98-4908W-5000-07 | 5,0mL IPV | |

| Confluent IPVS for Cavro XP-3000 Pumps | ||

| With 3-Way Ceramic "Y" Valve | ||

| 98-4911-50-07 | 50µL IPV | |

| 98-4911-100-07 | 100µL IPV | |

| 98-4911-250-07 | 250µL IPV | |

| 98-4911-500-07 | 500µL IPV | |

| 98-4911-1000-07 | 1.0mL IPV | |

| 98-4911-2500-07 | 2.5mL IPV | |

| 98-4911-5000-07 | 5,0mL IPV | |

| With 3-Way Ceramic "Y" Valve and Seal Wash Port | ||

| 98-4911 W-50-07 | 50µL IPV | |

| 98-4911W-100-07 | 100µL IPV | |

| 98-4911 W-250-07 | 250µL IPV | |

| 98-4911 W-500-07 | 500µL IPV | |

| 98-4911 W-1000-07 | 1.0mL IPV | |

| 98-4911W-2500-07 | 2.5mL IPV | |

| 98-4911 W-5000-07 | 5,0mL IPV | |

siehe auch: Adapter für Peristaltikpumpen / Schläuche für Peristaltikpumpen